When it comes to choosing the right material for tarpaulins, PE (Polyethylene) and PVC (Polyvinyl Chloride) stand out as the top contenders. Both materials offer unique advantages, making them suitable for a range of applications. In this comprehensive guide, we'll explore the features, benefits, and uses of PE and PVC tarpaulins, helping you make an informed decision for your specific needs.

Understanding Tarpaulins

What Are Tarpaulins?

Tarpaulins, commonly known as tarps, are large sheets of waterproof material often used to cover and protect objects from environmental elements like rain, wind, and sunlight.

What is PE (Polyethylene), and What is it Used For?

Polyethylene stands as a versatile thermoplastic, distinguished by its adaptable crystalline structure, which opens the door to a myriad of uses based on its specific type. This material ranks among the most abundantly manufactured plastics globally, with annual production reaching millions of tons. The breakthrough in polyethylene production emerged in the 1950s, thanks to the pioneering work of Karl Ziegler from Germany and Giulio Natta from Italy, who developed the revolutionary Ziegler-Natta catalysts.

This plastic comes in various forms, each tailored for specific uses. High-Density Polyethylene (HDPE), known for its higher crystallinity, serves purposes distinct from those of Low-Density Polyethylene (LDPE). LDPE is commonly found in everyday plastic products like grocery bags and cling films. In contrast, HDPE finds its niche in the construction industry, notably in making drain pipes. On the high end of the spectrum, Ultrahigh Molecular Weight Polyethylene (UHMW) is utilized in advanced applications, including medical equipment and bulletproof vests, owing to its exceptional performance characteristics.

What Are the Different Types of Polyethylene?

Polyethylene, a common and versatile plastic, comes in various forms, including several major types like LDPE, LLDPE, HDPE, and Ultrahigh Molecular Weight Polypropylene [2]. Other notable varieties are Medium Density Polyethylene (MDPE), Ultra-low-molecular-weight polyethylene (ULMWPE or PE-WAX), High-molecular-weight polyethylene (HMWPE), High-density cross-linked polyethylene (HDXLPE), Cross-linked polyethylene (PEX or XLPE), Very-low-density polyethylene (VLDPE), and Chlorinated polyethylene (CPE).

Low-Density Polyethylene (LDPE) is known for its flexibility and unique flow characteristics, making it ideal for applications like shopping bags and plastic films. Despite its high ductility, LDPE's tensile strength is relatively low, which is why it tends to stretch under pressure.

Linear Low-Density Polyethylene (LLDPE) shares similarities with LDPE but has added benefits. Its properties can be tweaked through formula adjustments, and its production is generally more energy-efficient than that of LDPE.

High-Density Polyethylene (HDPE) is a durable and somewhat rigid plastic, characterized by a highly crystalline structure. It's commonly used in containers for milk, laundry detergents, garbage bins, and even in kitchen cutting boards.

Ultrahigh Molecular Weight Polyethylene (UHMW) represents a denser variant of polyethylene, with molecular weights significantly higher than HDPE. This type of polyethylene can be transformed into ultra-strong threads, surpassing the tensile strength of steel, and is a key material in bulletproof vests and other high-performance gear.

What are the Characteristics of Polyethylene?

Understanding the uses of polyethylene leads us to explore its fundamental properties. Classified as a "thermoplastic" - unlike "thermoset" plastics - polyethylene's behavior in response to heat is noteworthy. Thermoplastics like PE become liquid at their melting points, which for LDPE and HDPE are around 110-130 degrees Celsius, respectively. A key advantage of thermoplastics is their ability to be heated to melting, cooled down, and reheated without significant quality loss. Unlike burning, polyethylene and similar thermoplastics melt, enabling easy injection molding and recycling. In contrast, thermoset plastics are heat-malleable only once, typically during molding. Heating them results in a permanent chemical change akin to a 2-part epoxy setting, and re-heating would cause them to burn, making them unsuitable for recycling.

The crystalline structure in different polyethylene types varies significantly. Less crystalline (or amorphous) plastics tend to soften gradually, displaying a broader range between their glass transition temperature and melting point. Conversely, crystalline plastics transition sharply from solid to liquid.

Polyethylene is a homopolymer, meaning it's made up of only one type of monomer unit, in this case, ethylene (CH2=CH2).

PE Tarpaulins: Features and Benefits

- Lightweight and Durable: PE tarpaulins are known for their lightweight yet durable nature, making them easy to handle and long-lasting.

- Weather Resistance: They offer excellent resistance to various weather conditions, ensuring reliable protection.

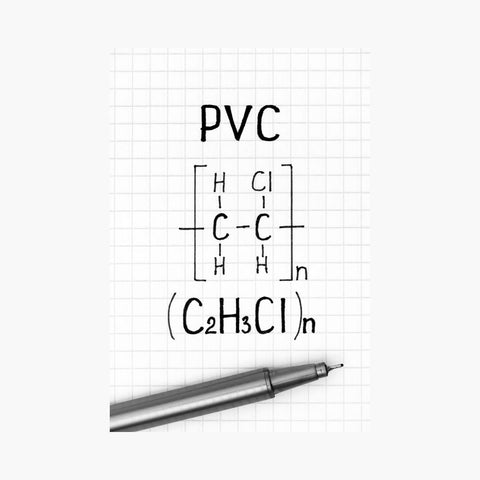

What is PVC, and What is it Used For?

PVC, an acronym for Polyvinyl Chloride, is a synthetic thermoplastic polymer that has cemented its role as one of the most widely used plastics worldwide. Its production journey echoes a history of innovation and adaptability, mirroring the evolution seen in the polyethylene industry.

The unique molecular structure of PVC is what sets it apart. This structure grants it the versatility to be manufactured in both rigid and flexible forms. Rigid PVC, often seen in construction, is known for its durability and resistance to environmental elements, making it an ideal material for window frames and pipes. On the other hand, flexible PVC finds its applications in areas requiring more pliability, such as electrical cable insulation and inflatable products.

PVC's widespread use can be attributed to its exceptional properties. It is not only strong and lightweight but also resistant to chemicals, water, and fire. These characteristics make it an indispensable material in various industries. In the medical field, PVC is used for blood bags and tubing, leveraging its non-reactive nature. In everyday life, it's found in products ranging from credit cards to vinyl flooring, underscoring its ubiquity.

The story of PVC's rise to prominence is a testament to the endless possibilities of plastic materials when shaped by human ingenuity and technological advancement. Just as polyethylene was revolutionized by the work of Ziegler and Natta, PVC continues to evolve, finding new uses and applications in a world that increasingly values versatility and durability in materials.

What Are the Different Types of PVC?

Polyvinyl Chloride, commonly known as PVC, is one of the most versatile and widely used synthetic materials in the world. Its applications range from construction and healthcare to electronics and automotive industries. Understanding the different types of PVC is essential for choosing the right material for your project.

Types of PVC

Rigid PVC (uPVC):

Description: Unplasticized PVC, or uPVC, is a stiff and cost-effective plastic.

Uses: Widely used in construction for pipes, window frames, and doors.

Flexible PVC:

Description: This type incorporates plasticizers to make it flexible.

Uses: Ideal for hoses, electrical cable insulation, and inflatable products.

Chlorinated PVC (CPVC):

Description: CPVC is PVC that has been chlorinated, resulting in improved resistance to heat and chemicals.

Uses: Often used for hot water pipes and industrial liquid handling.

Molecular Oriented PVC (PVC-O):

Description: PVC-O undergoes a special production process to enhance its strength and durability.

Uses: Mainly used in water supply systems due to its high pressure resistance.

PVC-M and PVC-H:

Description: These are modified types of PVC, with PVC-M offering enhanced flexibility and PVC-H providing increased hardness.

Uses: PVC-M is used in pressure pipes and fittings, while PVC-H finds its application in more demanding construction roles.

The versatility of PVC lies in its ability to be manufactured in different forms, each suited to specific needs and applications. Whether it's for rigid construction materials or flexible tubing, understanding these variations of PVC is crucial for making an informed decision for your specific requirements.

What are the Characteristics of PVC?

Polyvinyl Chloride, commonly known as PVC, is a type of plastic widely recognized for its diverse applications in various industries. Its unique characteristics make it a preferred choice for a range of products. Here, we delve into the key attributes that define PVC:

Durability and Strength: PVC is renowned for its durability. It resists corrosion, chemicals, and weathering, making it ideal for outdoor and high-stress applications. This strength ensures a long life for products made from PVC, often exceeding decades.

Lightweight Nature: Despite its strength, PVC is relatively lightweight. This makes it easy to handle, transport, and install, reducing overall costs and making it a practical choice for many construction and packaging applications.

Versatility: One of PVC's standout features is its versatility. It can be manufactured in various colors and forms, including rigid and flexible options. This adaptability allows PVC to be used in a wide array of products, from medical devices to construction materials.

Thermal Insulation: PVC provides excellent thermal insulation. This property is particularly beneficial in the building sector, where it is used for window frames and doors, contributing to energy efficiency in homes and commercial buildings.

Electrical Insulation: PVC is a good insulator, which makes it a safe material for electrical applications. This characteristic is crucial for wiring and cabling, where safety and reliability are paramount.

Water Resistance: Being water-resistant, PVC is commonly used in plumbing and outdoor applications. Its ability to withstand moisture without deteriorating adds to its longevity and functionality.

Recyclability: While PVC is a type of plastic, it is recyclable. Its ability to be reprocessed and reused helps in reducing environmental impact, making it a more sustainable option than some other plastics.

Cost-Effectiveness: PVC is not only efficient in performance but also in cost. Its ease of production and longevity make it a cost-effective material for both manufacturers and consumers.

The characteristics of PVC such as its durability, lightweight nature, versatility, insulation properties, water resistance, recyclability, and cost-effectiveness make it an indispensable material in various sectors. Understanding these properties helps in appreciating why PVC continues to be a popular choice in today's market.

Comparing PE and PVC Tarpaulins

PE vs. PVC: While PE tarps are great for light to medium-duty tasks, PVC tarps are preferred for more demanding applications due to their superior strength and durability.

Choosing the Right Tarpaulin

Consider Your Needs: The choice between PE and PVC tarpaulins depends on factors like the purpose, duration of use, and environmental conditions.

PE and PVC tarpaulins offer distinct advantages. Your choice should align with your specific requirements, ensuring effective protection and durability.

Sources:

[1]: https://www.creativemechanisms.com/blog/polyethylene-pe-for-prototypes-3d-printing-and-cnc

[2]: https://www.sciencedirect.com/topics/materials-science/polyethylene

[3]: https://www.britannica.com/science/plastic

[4]: https://www.britannica.com/science/polyethylene

[5]: https://www.mordorintelligence.com/industry-reports/linear-low-density-polyethylene

[6]: https://www.sciencedirect.com/topics/chemistry/ultra-high-molecular-weight-polyethylene

[8]: https://www.researchgate.net/publication/285973599_The_History_of_Polyethylene